Wholesale Discount Light Weight Brick Making Machine - QT6-15 block machine – Honcha

Wholesale Discount Light Weight Brick Making Machine - QT6-15 block machine – Honcha Detail:

——Features——

1.Block Making machine nowadays is widely used in construction for the mass production of blocks/pavers/slabs which are manufactured from concrete.

2. QT6-15 block machine model is made by HONCHA with more than 30 years’ experiences. And its stable reliable working performance plus low maintenance costs make it as the favorite model among HONCHA customers.

3. With a production height of 40-200mm, customers can get back their investments within short time by its maintenance-free productivity.

4.Honcha’s unique distribution system combines Traveling Material Bin and enclosed belt conveyor, the system’s continuous movement is controlled by photoelectric switch. Thus make it easy to change the raw material mixing ratio and ensures promptitude and accuracy.

——Model Specification——

| QT6-15 Model Specification | |

| Main Dimension(L*W*H) | 3150X217 0×2650(mm) |

| Usetu Mouding Aea(LW”H) | 800X600X40~200(mm) |

| Pallet Size(LW”H) | 850X 680X 25(mm/bamboo pallet) |

| Pressure Rating | 8~1 5Mpa |

| Vibration | 50~7OKN |

| Vibration Frequency | 3000~3800r/min |

| Cycle Time | 15~2 5s |

| Power (total) | 25/30kw |

| Gross Weight | 6.8T |

★For reference only

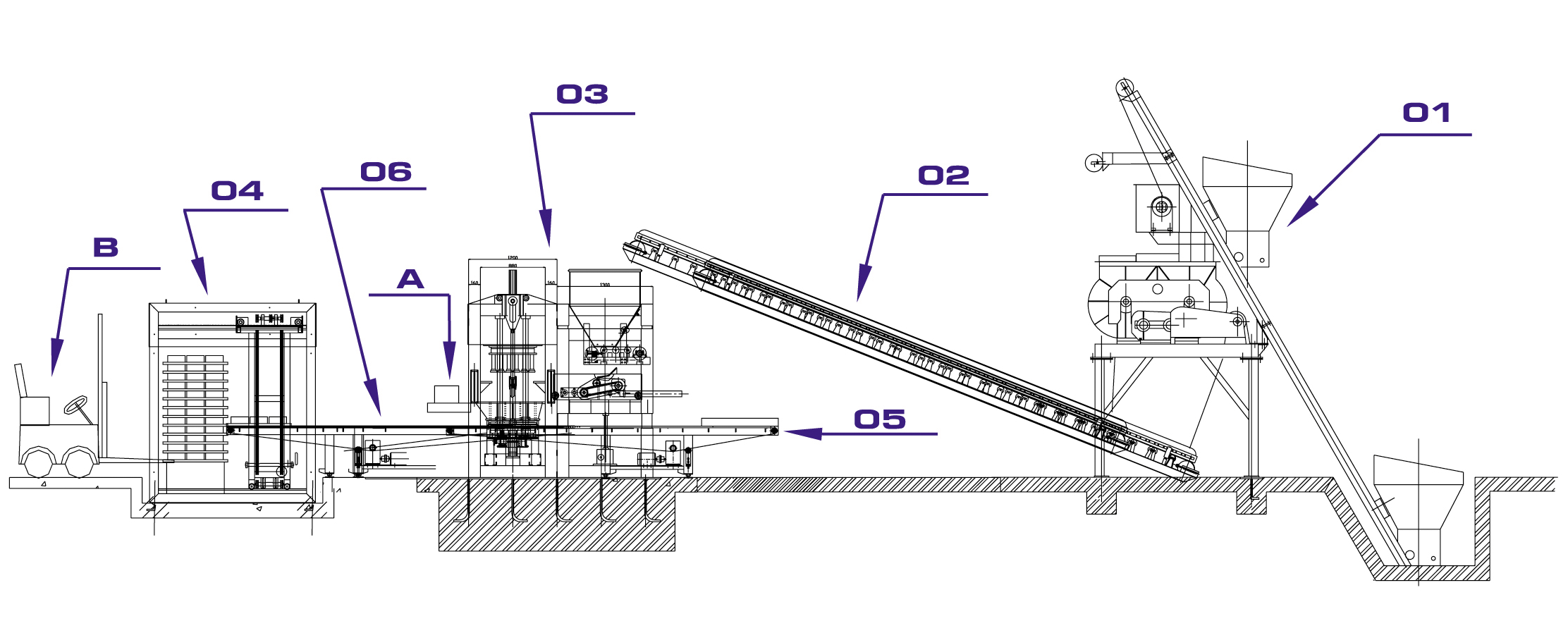

——Simple Production Line——

| ITEM | MODEL | POWER |

| 01 Enhanced Mixer | JS500 | 25kw |

| 02 Dry mix conveyor | By Order | 2.2kw |

| 03 QT 6-15 Block Machine | QT 6-15 Type | 25/30kw |

| 04 Automaic Stacker | For QTS-15 System | 3kw |

| 05 Pallets Conveying System | For QTS-15 System | 1.5kw |

| 06 Blocks Conveying System | For QTS-15 System | 0.75kw |

| A Block Sweeper | For QTS-15 System | 0.018kw |

| B Face Mix Section (optional) | For QTS-15 System | |

| Fork Lift(Optional) | 3T |

★The above items can be reduced or added as needed. such as: cement silo(50-100T),screw conveyor, batching machine, automatic pallet feeder ,wheel loader, folk lift, air compressor.

Automatic packing machine

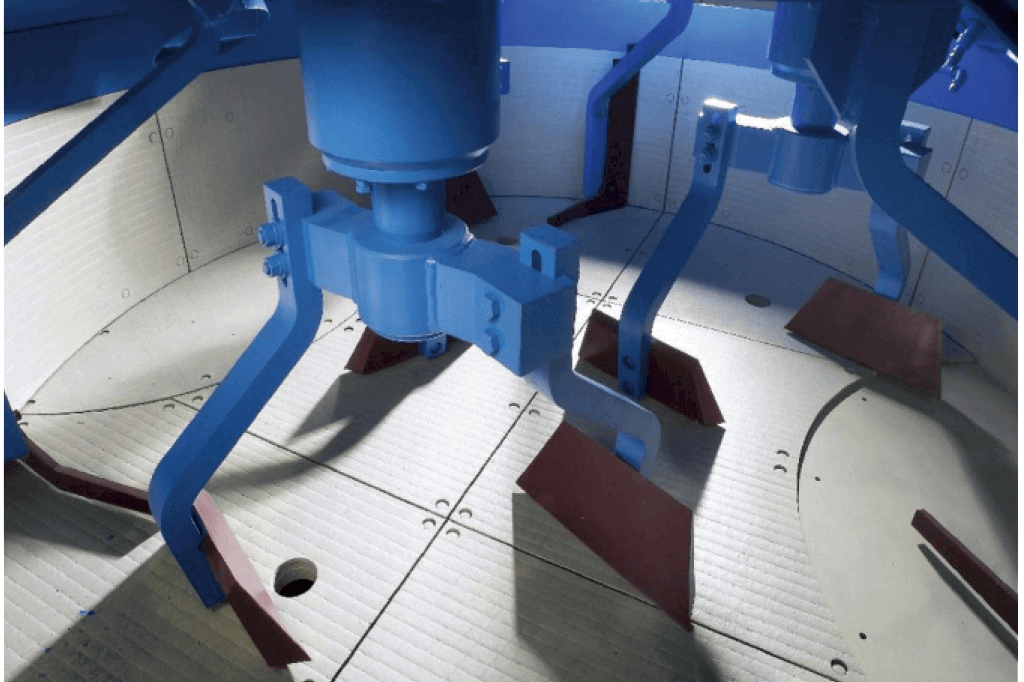

Planettary mixer

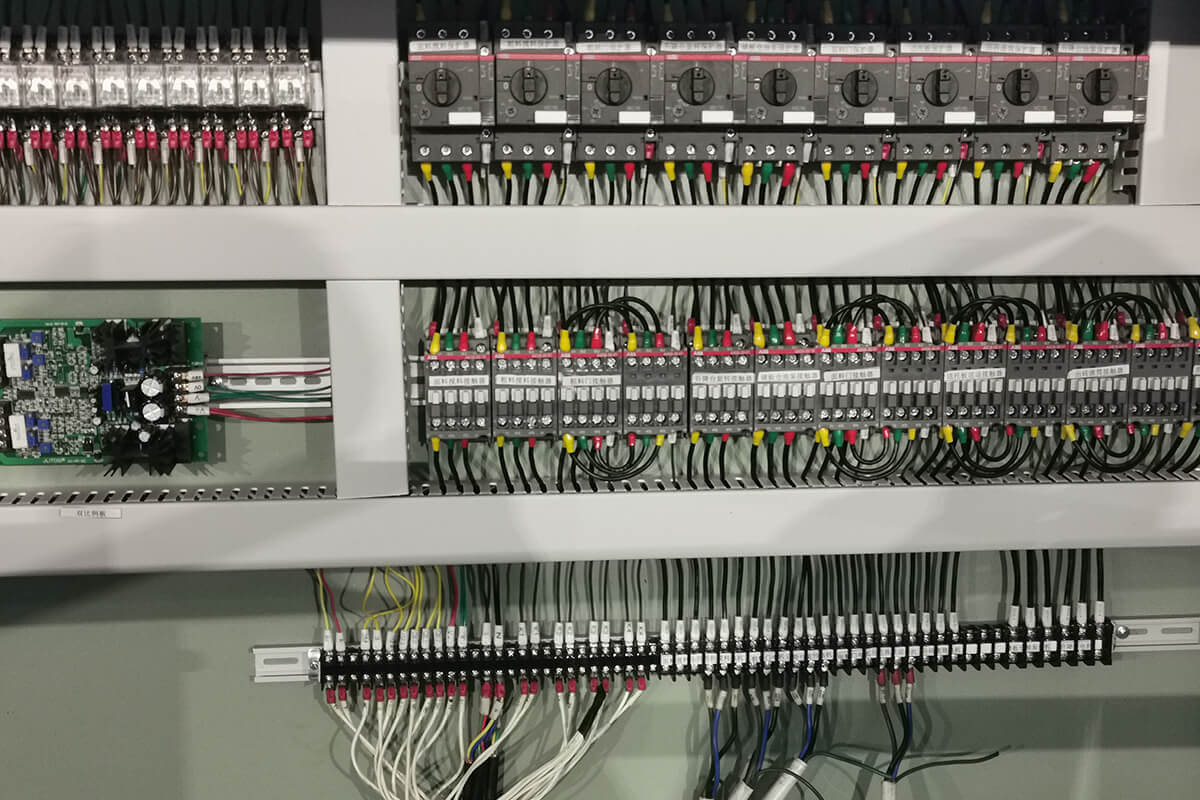

Control panel

Batching machine

—— Production Capacity——

★Other brick sizes not mentioned may provide drawings to inquire about specific production capacity.

Product detail pictures:

Related Product Guide:

High-quality comes 1st; assistance is foremost; business enterprise is cooperation" is our business enterprise philosophy which is constantly observed and pursued by our business for Wholesale Discount Light Weight Brick Making Machine - QT6-15 block machine – Honcha , The product will supply to all over the world, such as: Sheffield, Mexico, Philadelphia, We integrate all our advantages to continuously innovate, improve and optimize our industrial structure and product performance. We will always believe in and work on it. Welcome to join us to promote green light, together we will make a better Future!

This company has the idea of "better quality, lower processing costs, prices are more reasonable", so they have competitive product quality and price, that's the main reason we chose to cooperate.

+86-13599204288

+86-13599204288