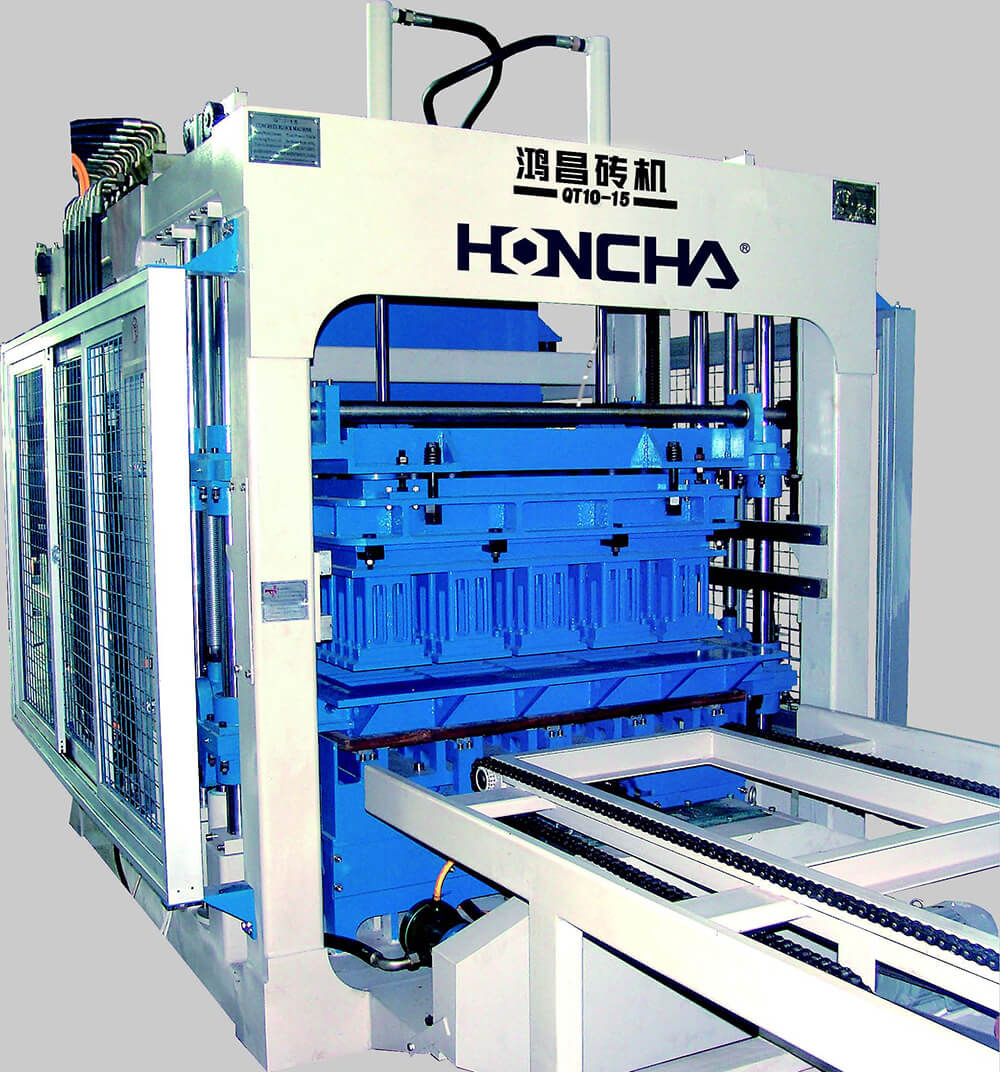

Renewable Design for Interlock Brick Machine - QT10-15 block machine – Honcha

Renewable Design for Interlock Brick Machine - QT10-15 block machine – Honcha Detail:

——Features——

1. It can realize vertical production and optional layered material displacement, which can increase output and get a better appearance of products.

2. Improved synchronous table vibration system effectively transmits the maximum vibration to the mould box, thus greatly increase block quality and at the same time extend the

3. With a production height of 40-400mm, it is applicable to the production of large block products, large pieces of hydraulic revetment and road traffic stone, etc.

4. Honcha’s unique distribution system combines Traveling Material Bin and enclosed belt conveyor, the system’s continuous movement is controlled by photoelectric switch. Thus make it easy to change the raw material mixing ratio and ensures promptitude and accuracy.

——Model Specification——

|

QT10-15 Model Specification |

|

| Main Dimension(L*W*H) | 3950*2650*2800mm |

| Useful Moulding Area(L*W*H) | 1030*830*40-200mm |

| Pallet Size(L*W*H) | 1100*880*30mm |

| Pressure Rating | 8-15Mpa |

| Vibration | 70-100KN |

| Vibration Frequency | 2800-4800r/min (adjustment) |

| Cycle Time | 15-25s |

| Power(total) | 48KW |

| Gross Weight | 12T |

★For reference only

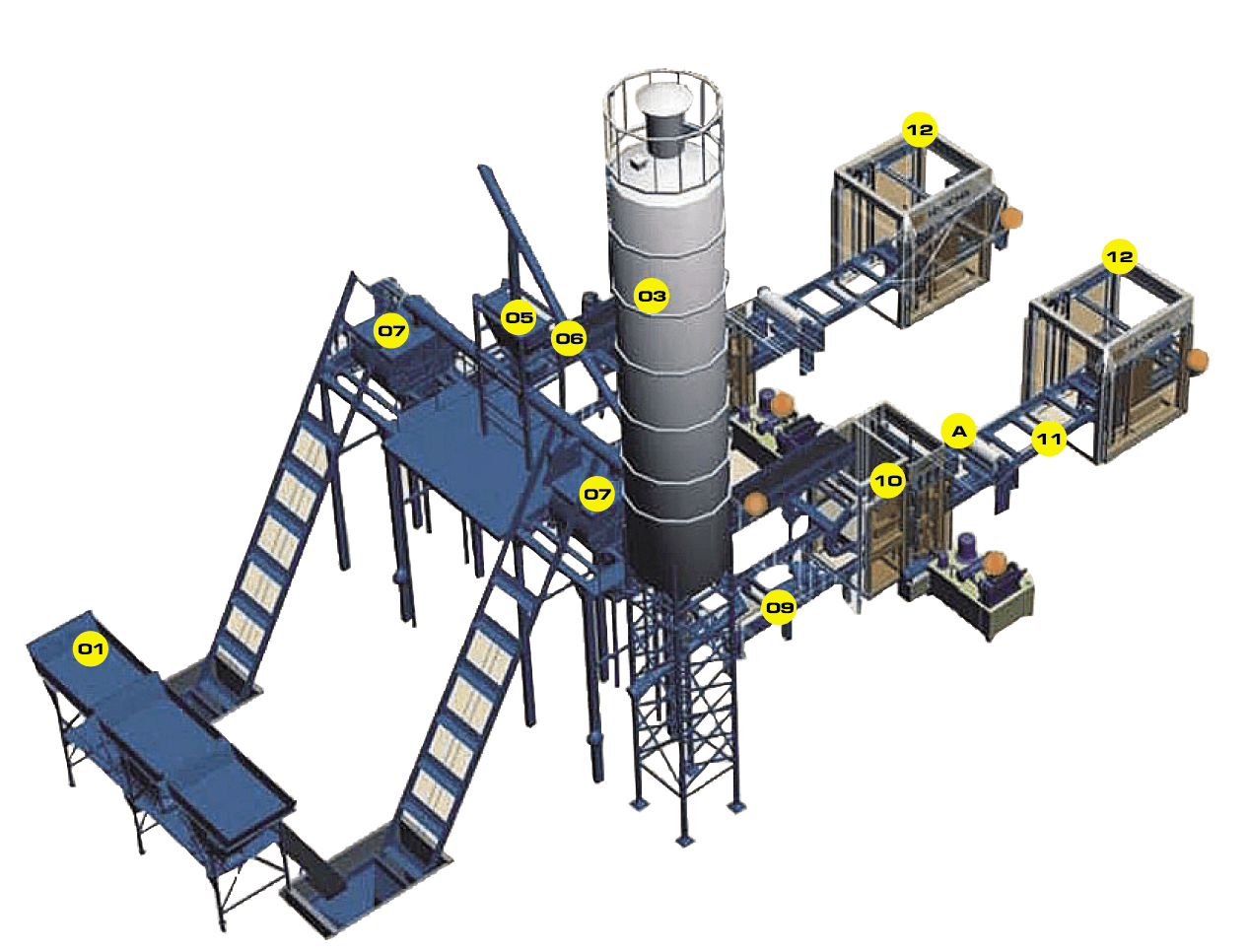

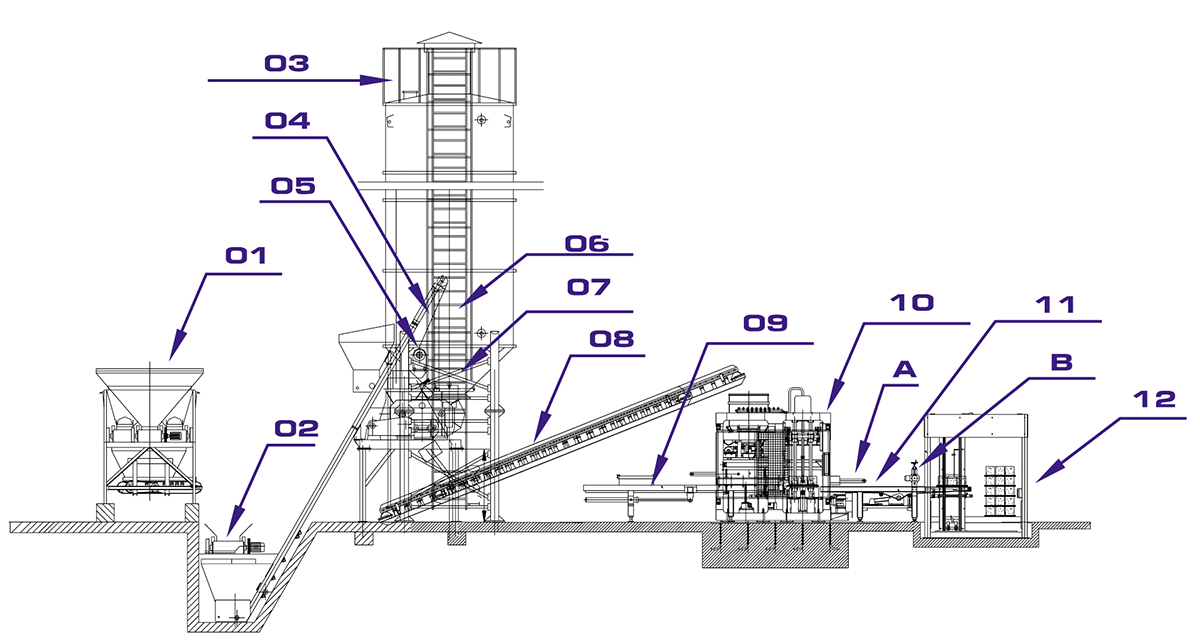

——Simple Production Line——

|

ITEM |

MODEL |

POWER |

| 01 3-Compartments Batching Station | PL1600 III | 13KW |

| 02 Belt Conveyor | 6.1m | 2.2KW |

| 03 Cement silo | 50T | |

| 04 Water Scale | 100KG | |

| 05 Cement Scale | 300KG | |

| 06 Screw Conveyor | 6.7m | 7.5KW |

| 07 Enhanced Mixer | JS750 | 38.6KW |

| 08 Dry Mix Conveyor | 8m | 2.2KW |

| 09 Pallets Conveying System | For QT10-15 System | 1.5KW |

| 10 QT10-15 Block Machine | QT10-15 System | 48KW |

| 11 Block Conveying System | For QT10-15 System | 1.5KW |

| 12 Automatic Stacker | For QT10-15 System | 3.7KW |

| A Face Mix Section(Optional) | For QT10-15 System | |

| B Block Sweeper System(Optional) | For QT10-15 System |

★The above items can be reduced or added as needed. such as: cement silo(50-100T),screw conveyor, batching machine, automatic pallet feeder ,wheel loader, folk lift, air compressor.

—— Production Capacity——

★Other brick sizes not mentioned may provide drawings to inquire about specific production capacity.

Product detail pictures:

Related Product Guide:

We are also specializing in improving the things management and QC method in order that we could retain terrific edge inside the fiercely-competitive small business for Renewable Design for Interlock Brick Machine - QT10-15 block machine – Honcha , The product will supply to all over the world, such as: Johannesburg, St. Petersburg, Mauritania, They're durable modeling and promoting well all over the world. Under no circumstances disappearing key functions in a brief time, it's a should for you personally of fantastic quality. Guided by the principle of Prudence, Efficiency, Union and Innovation. the business make an awesome efforts to expand its international trade, raise its enterprise. rofit and improve its export scale. We are confident that we'll have a vibrant prospect and to be distributed all over the world in the years to come.

The sales manager has a good English level and skilled professional knowledge, we have a good communication. He is a warm and cheerful man, we have a pleasant cooperation and we became very good friends in private.

+86-13599204288

+86-13599204288