Palletizer is an automated equipment widely used in the field of industrial production, especially in packaging and logistics links. It is mainly used to neatly stack produced products, such as bagged, boxed, and canned items, on pallets, skids, or other carriers in a certain arrangement order and layers to form a stable stack shape, so as to facilitate subsequent operations such as warehousing, transportation, loading and unloading.

In terms of structure and functional modules, a palletizer usually includes key parts such as a conveying system, a grasping and placing device, a control system, and a frame. The conveying system is responsible for conveying the items to be palletized to the working area of the palletizer in an orderly manner, ensuring that the items can accurately reach the designated position and preparing for subsequent grasping operations. The grasping and placing device is the core executive component of the palletizer. It can adopt different grasping methods, such as mechanical grippers, vacuum suction cups, clamping mechanisms, etc., according to the shape, size and weight of different items, to accurately grasp the items and place them smoothly to the corresponding positions according to the preset stacking mode, so as to realize the orderly stacking of items. The control system is the “brain” of the palletizer. It accurately controls the entire palletizing process through built-in programs and algorithms, including the running speed of the conveying system, the action sequence of the grasping device, the position and layers of stacking, etc., to ensure the automation and efficiency of the palletizing process. The frame provides a stable support structure for each component of the palletizer, ensuring the stability and reliability of the equipment during operation.

In terms of workflow, when the items to be palletized enter the working range of the palletizer through the conveying system, the control system will send instructions to the grasping and placing device according to the preset parameters and the current working status. The grasping device acts quickly, grabs the items accurately, and then moves the items to the designated position above the pallet according to the planned stacking path and puts them down slowly to complete the stacking of one layer of items. After that, the conveying system continues to convey the next batch of items, and the grasping device repeats the above actions to stack the next layer. This cycle continues until the pallet is stacked to the set number of layers to form a complete stack. The pallet that has completed stacking will be transported away from the working area of the palletizer by the conveying system and enter the warehousing or transportation link.

Palletizers have many significant advantages. First is efficiency. It can continuously carry out palletizing operations at a relatively fast speed, which greatly improves production efficiency compared with manual palletizing and can meet the efficient operation needs of large-scale production enterprises. Second is accuracy. Through the precise control system and mechanical structure, the palletizer can ensure that each item is accurately placed in the predetermined position, and the stacked shape is neat and stable, avoiding problems such as misalignment and inclination that may occur in manual palletizing, which is conducive to the safety of goods warehousing and transportation. Third is stability. The palletizer can run stably for a long time and is not easily affected by factors such as personnel fatigue and emotions, which can ensure the continuity and stability of the production process and improve the production management level of enterprises. In addition, in terms of labor intensity and cost, the application of palletizers greatly reduces the labor intensity of workers and reduces enterprises’ dependence on labor. Especially in some palletizing scenarios with high labor intensity and harsh working environments (such as high temperature, low temperature, dust, noise, etc.), it not only ensures the health of workers but also can reduce the labor cost of enterprises to a certain extent.

With the continuous development of industrial automation technology, palletizers are also continuously upgraded and iterated. Modern palletizers increasingly integrate advanced technologies such as artificial intelligence and machine vision. The application of machine vision technology enables palletizers to recognize the shape, color, position and other information of items in real time through visual sensors such as cameras, further improving the accuracy of grasping and placing. Even if there is a position deviation of items during the conveying process, it can be automatically adjusted and compensated. Artificial intelligence technology can enable palletizers to have a certain learning and optimization ability, automatically adjust the stacking strategy according to different production tasks and item characteristics, and realize more intelligent and efficient palletizing operations.

In short, as one of the important equipment for industrial automation, palletizers play an irreplaceable role in modern industrial production. They not only improve the production efficiency and product quality of enterprises but also promote the automation and intelligent development of the entire production process, providing strong support for enterprises’ cost reduction, efficiency increase and sustainable development.

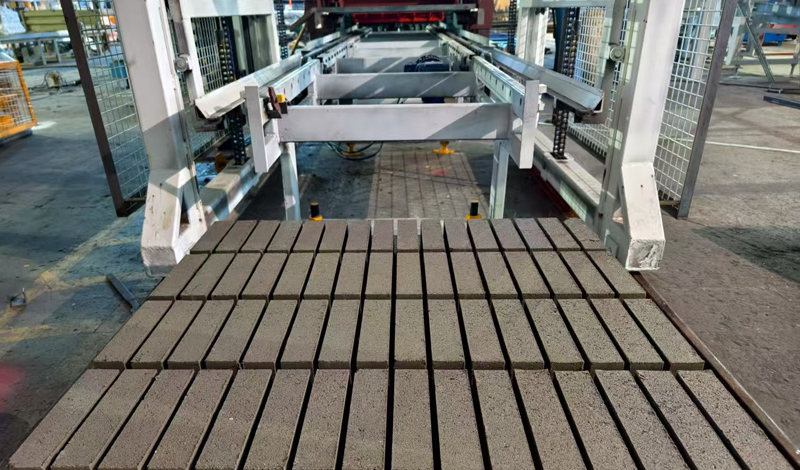

The machine in the picture is a palletizer.

The palletizer is a key automated equipment in industrial production, especially in the fields of packaging and logistics. It is mainly used to neatly stack various products such as bagged, boxed, and canned ones on carriers like pallets in a specific order and layers to form a stable stack shape, facilitating subsequent warehousing, transportation, loading and unloading.

In terms of structure, a palletizer consists of parts such as a conveying system, a grasping and placing device, a control system, and a frame. The conveying system orderly sends the items to be palletized into the working area; the grasping and placing device is the core, which can accurately grasp items by means of mechanical grippers, vacuum suction cups, etc. according to the shape of the items and place them according to a preset mode; the control system, as the “brain”, accurately controls the conveying speed, grasping sequence, stacking position and layers through program algorithms to ensure automation and efficiency; the frame provides stable support for each component.

During operation, the items to be palletized enter the working range through the conveying system, and the control system sends instructions to the grasping and placing device according to parameters and status. The grasping device quickly grabs the items, moves them along the planned path to the designated position above the pallet and slowly places them down to complete the stacking of one layer. After that, the conveying system sends the next batch of items, and the grasping device repeats the action to stack the next layer. The cycle continues until the pallet reaches the set number of layers to form a complete stack, and then it is transported away by the conveying system to enter the warehousing or transportation link.

Palletizers have significant advantages, being efficient, accurate and stable. They can reduce the labor intensity of workers and the labor costs of enterprises, and also ensure operations in harsh environments. With the development of industrial automation, they also integrate technologies such as artificial intelligence and machine vision to further improve accuracy and intelligence, helping enterprises reduce costs, increase efficiency and achieve sustainable development.

Post time: Sep-05-2025

+86-13599204288

+86-13599204288