Marathon 64 is your best choice for

Marathon 64 is your best choice for

-Economic

-Durability

-High Productivity

-High Quality

with wide range of products such as concrete blocks, pavers, kerbs, retaining wall units, planters and etc.

——Basic configuration——

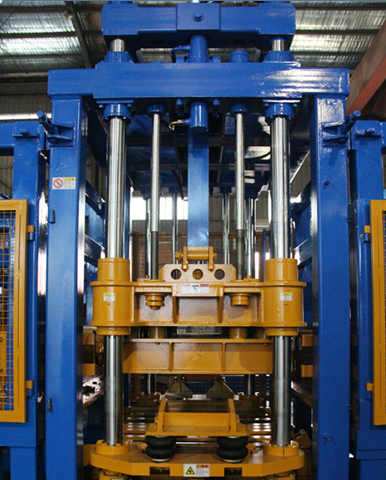

1.Main Machine

★The main frame is built of strong hollow and rectangle sections and process anti fatigue treatment after welding to strengthen the whole structure.

★All levelings and alignments of the main frame are strictly controlled within designed requirement.

★All wearing parts are designed for easily changeable purpose in order to minimize regular maintenance time.

★Most of the screws and nuts replace welding, easy disassembly and maintenance

★The one-piece molding structure, extended shaft sleeve, and new type of guide pillar components make the molding mechanism into a whole, which can run more smoothly, accurately, and have a longer service life.

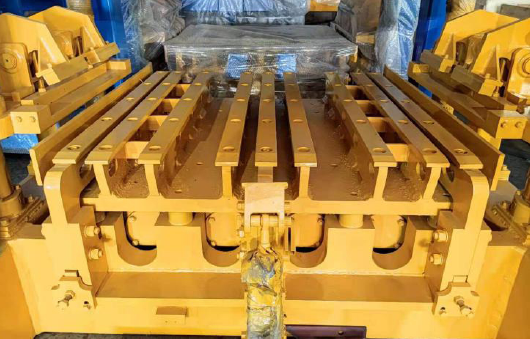

2. Base material device

★Two strong driving arms are driven by two synchronized hydraulic cylinders.

★Filling box table roller, front liner and side liners are modified to be adjustable to avoid the materials escaping problem.

★Encoder is equipped in the driving arm to provide different speeds at different positions to fit different product filling criteria.

★The redesigned follow-up crank arm feeding device drives the feeding cart to move smoothly and quickly.

★Unique Swinging claw feeding device makes the feeding faster and more evenly.

★The hydraulic lifting system of the feeding frame designed for the model makes it easier and faster than ever to adjust the production of products of different heights.

★The hopper is positioned in the top of the frame.Use a 2.2kw motor to open and close the material gate, The mixing level gauge and internal design can effectively control the quantity and time of blanking.

3. Face material device

It is used to add functional surface or color to concrete brick.

The hydraulic lifting system of the feeding frame designed for the model makes it easier and faster than ever to adjust the production of products of different heights.

The hopper is positioned in the top of the frame.

4. Central control system

Thecontrol system adopts:

★Siemens man-machine interface + PLC

★Imported electrical components

★Wireless remote control device makes fault diagnosis and system upgrade easier.

——Model detail——

Vibration table

Hydraulic station

Air bag

PM motor

—— Production Capacity——

|

Production capacity |

||

|

Standard brick |

250*120*60 |

64pcs/mould |

|

hexagon |

115 |

25pcs/mould |

|

I-shape pavers |

200*165*60/80 |

35pcs/mould |

|

Hollow block |

400*200*200 |

12.5pcs/mould |

|

Pavers |

200*100*60 |

80pcs/mould |

——Model Specification——

|

Marathon 64 Model Specification |

|

| External dimension(MM) | 7500*2300*3600 |

| Total weight(KG) | 23000 |

| Pallet size(MM) | 1200*1150 |

| Molding area(MM) | 1120*1120 |

| Molding height(MM) | 50-300 |

| Molding cycle(S) | 15-25 |

| Excitation force(KN) | 180-240 |

| Power of vibration motor(KW) | 11*4 |

| Maximum revolutions of vibration motor(R) | 3000 |

★For reference only

+86-13599204288

+86-13599204288