High Performance otal Automatic Brick Making Machine - QT12-15 block machine – Honcha

High Performance otal Automatic Brick Making Machine - QT12-15 block machine – Honcha Detail:

——Features——

1.Newly developed screen feeder with agitators to ensure even and fast material feeding into the mould box. The claws inside the feeder are agitating continously to reduce the stickiness of dry mix before feeding.

2. Innovative synchronous table vibration system double the useful molding area, greatly increase block quality and capacity, at the same time extend the mould working life.

3.Genuine Germany imported Bosch Air Squeeze Buds for noise and vibration absorption.

——Model Specification——

|

QT12-15 Model Specification |

|

| Main Dimension(L*W*H) | 3200*2020*2750mm |

| Useful Moulding Area(L*W*H) | 1280*850*40-200mm |

| Pallet Size(L*W*H) | 1380*880*30mm |

| Pressure Rating | 8-15Mpa |

| Vibration | 80-120KN |

| Vibration Frequency | 3000-3800r/min (adjustment) |

| Cycle Time | 15-25s |

| Power(total) | 54.2KW |

| Gross Weight | 12.6T |

★For reference only

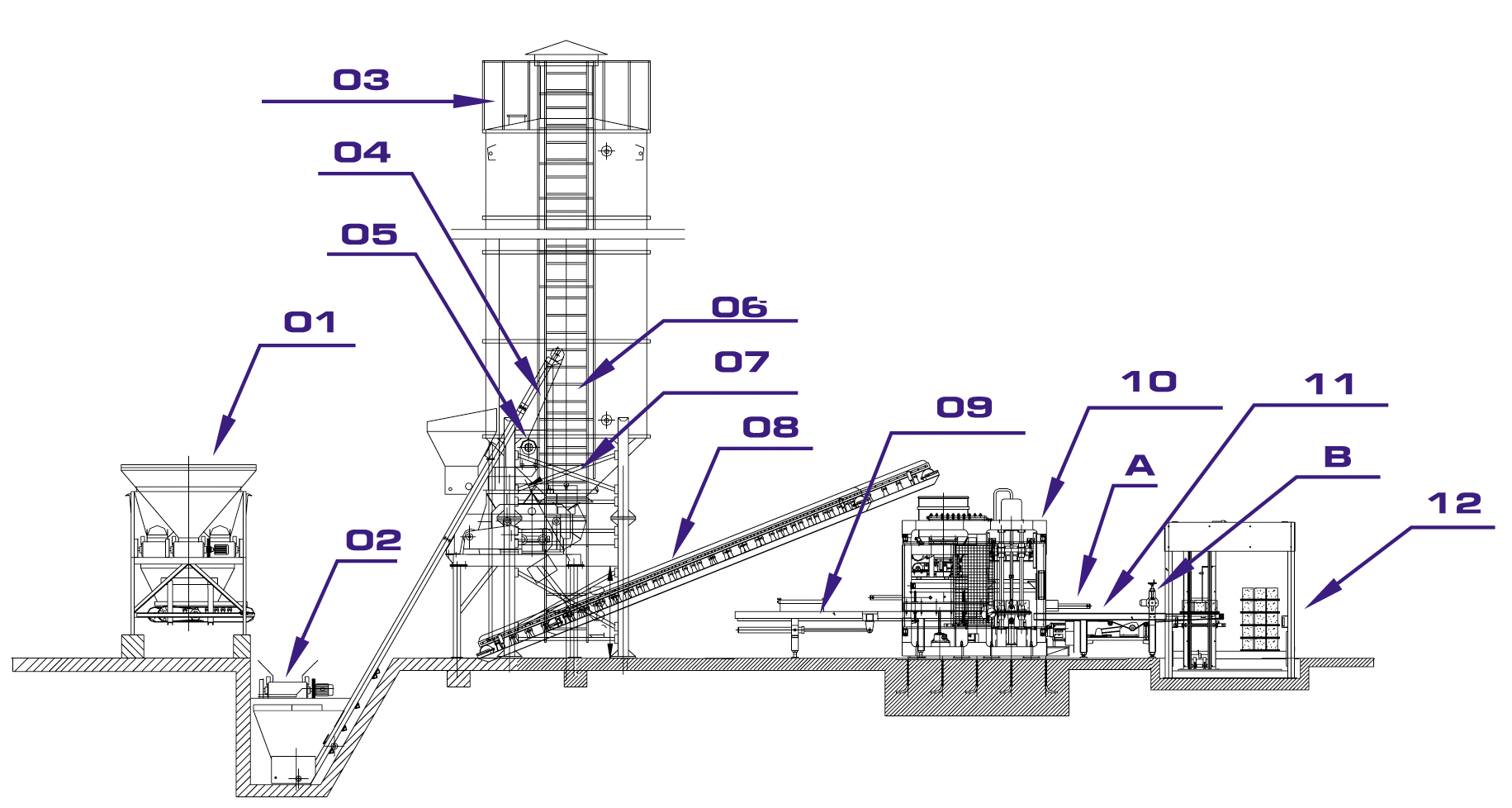

——Simple Production Line——

|

ITEM |

MODEL |

POWER |

| 01 3-Compartments Batching Station | PL1600 III | 13KW |

| 02 Belt Conveyor | 6.1m | 2.2KW |

| 03 Cement silo | 50T | |

| 04 Water Scale | 100KG | |

| 05 Cement Scale | 300KG | |

| 06 Screw Conveyor | 6.7m | 7.5KW |

| 07 Enhanced Mixer | JS1000 | 51KW |

| 08 Dry Mix Conveyor | 8m | 2.2KW |

| 09 Pallets Conveying System | For QT12-15 System | 1.5KW |

| 10 QT12-15 Block Machine | QT12-15 System | 54.2KW |

| 11 Block Conveying System | For QT12-15 System | 1.5KW |

| 12 Automatic Stacker | For QT12-15 System | 3.7KW |

| A Face Mix Section (Optional) | For QT12-15 System | |

| B Block Sweeper System(Optional) | For QT12-15 System |

★The above items can be reduced or added as needed. such as: cement silo(50-100T),screw conveyor, batching machine, automatic pallet feeder ,wheel loader, folk lift, air compressor.

—— Production Capacity——

★Other brick sizes not mentioned may provide drawings to inquire about specific production capacity.

Product detail pictures:

Related Product Guide:

As a way to present you with ease and enlarge our enterprise, we also have inspectors in QC Workforce and assure you our greatest support and solution for High Performance otal Automatic Brick Making Machine - QT12-15 block machine – Honcha , The product will supply to all over the world, such as: Accra, El Salvador, Philippines, Based on experienced engineers, all orders for drawing-based or sample-based processing are welcomed. We have now won a good reputation for outstanding customer service among our overseas customers. We will continue to try the best to supply you good quality products and solutions and the best service. We've been looking forward to serving you.

Customer service staff and sales man are very patience and they all good at English, product's arrival is also very timely, a good supplier.

+86-13599204288

+86-13599204288