Factory Price For Interlock Block Machine - Simple Automatic Concrete Block Production Line – Honcha

Factory Price For Interlock Block Machine - Simple Automatic Concrete Block Production Line – Honcha Detail:

——Features——

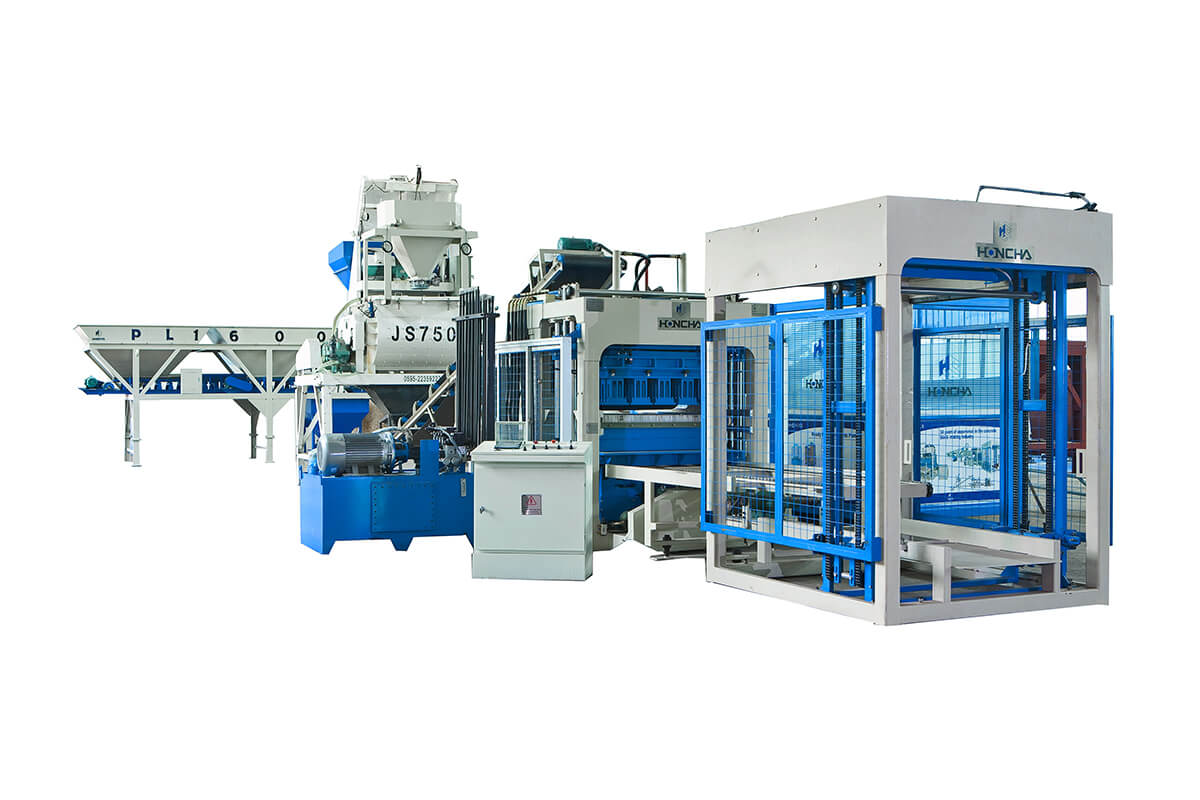

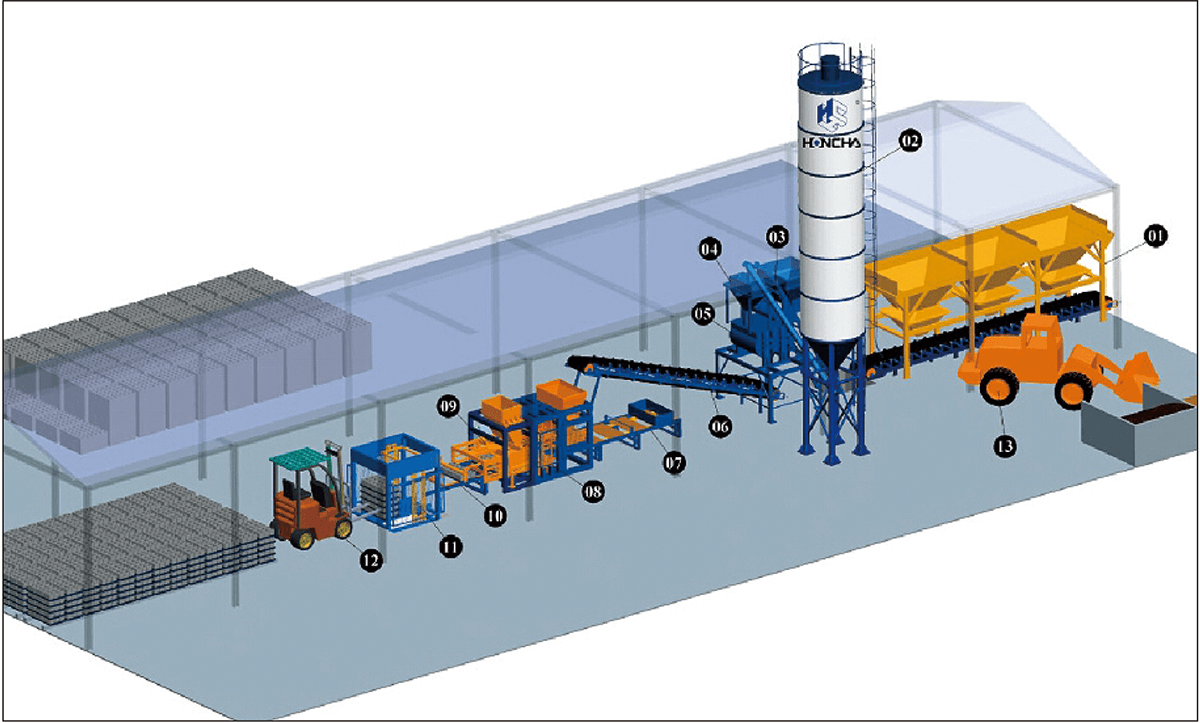

Simple production line: Putting different aggregates in the Batching Station, it will measure them to the required weight and then combine with the cement from cement silo. All of the materials will then be sent to the mixer. After being mix evenly, the belt conveyer will convey the materials to the Block Making Machine. The finished blocks after being cleaned by the block sweeper will be transferred to the stacker. The folk lift or two workers can take the blocks to the yard for natural curing.

——Component——

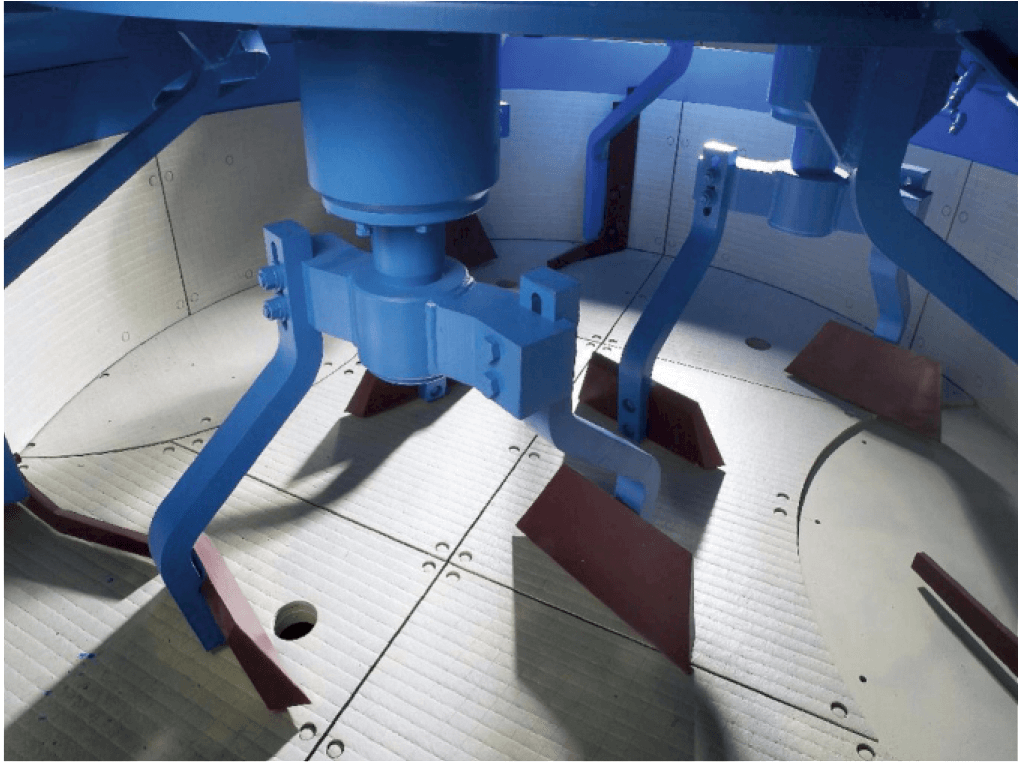

1 Batching and Mixing Plant

The batching and mixing system consists of a multi-component batching station which automatically weighs and conveys the aggregate to the compulsory mixer. The cement is transported from the cement silo using a screw conveyor and automatically weighed at the mixer. Once the mixer has completed its cycle the concrete will be transported using our overhead skip system to the fully automatic block machine system.

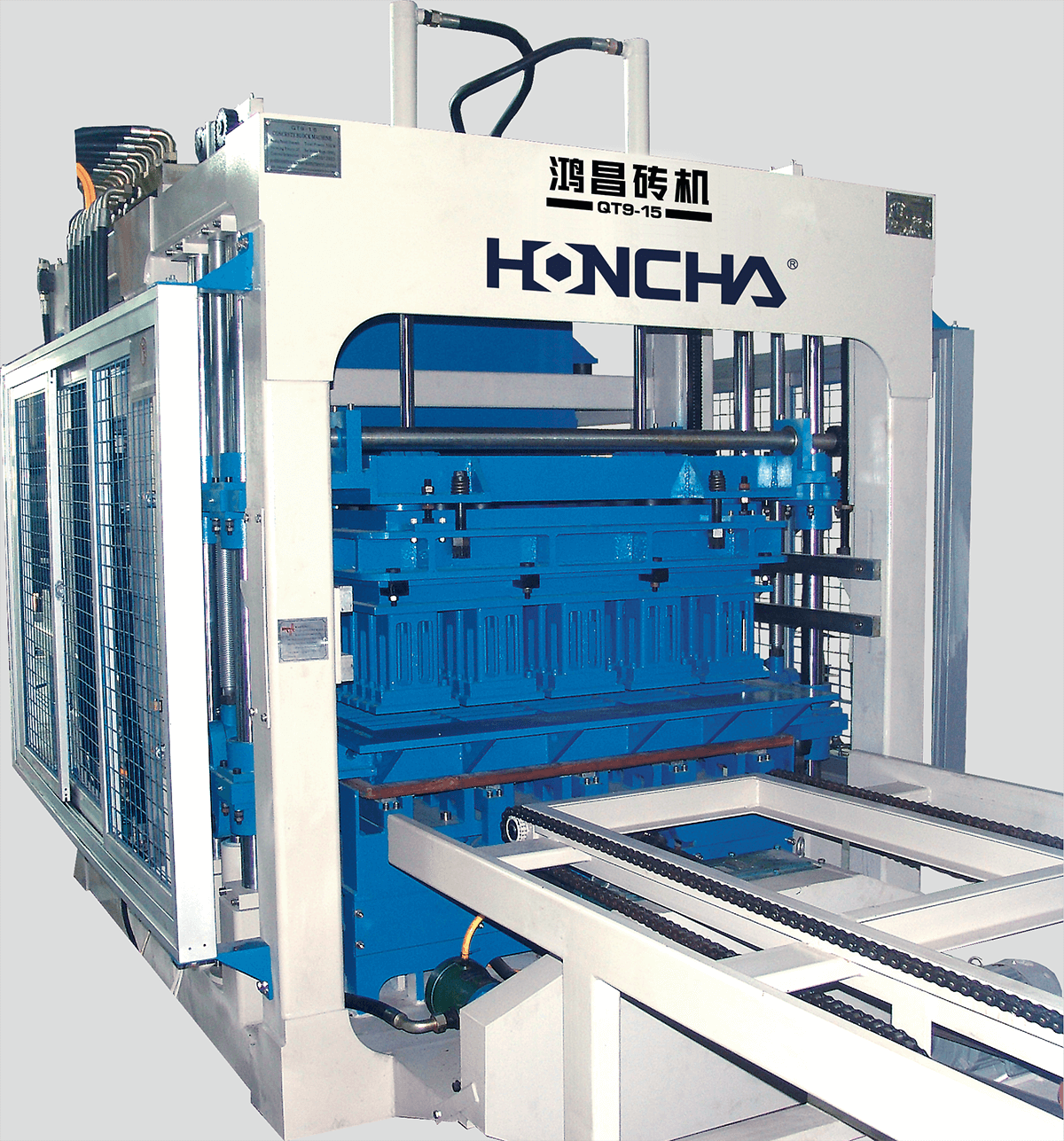

2、 Block machine

The concrete is pushed into place by a feeder box and spread evenly into the bottom female mould. The top male mould is then inserted into the bottom mould and the use synchronized table vibration from both moulds to compact the concrete into the desired block. The machine can have a fully automatic face mix section added to allow the production of colored pavers.

Optional block machine models:QT6-15,QT8-15,QT9-15,QT10-15,QT12-15.

3、Stacker

The fresh blocks are cleaned to make sure they are all the same height and then transported to the stacker. Then the fork lift will take all pallets of blocks to the yard for natural curing.

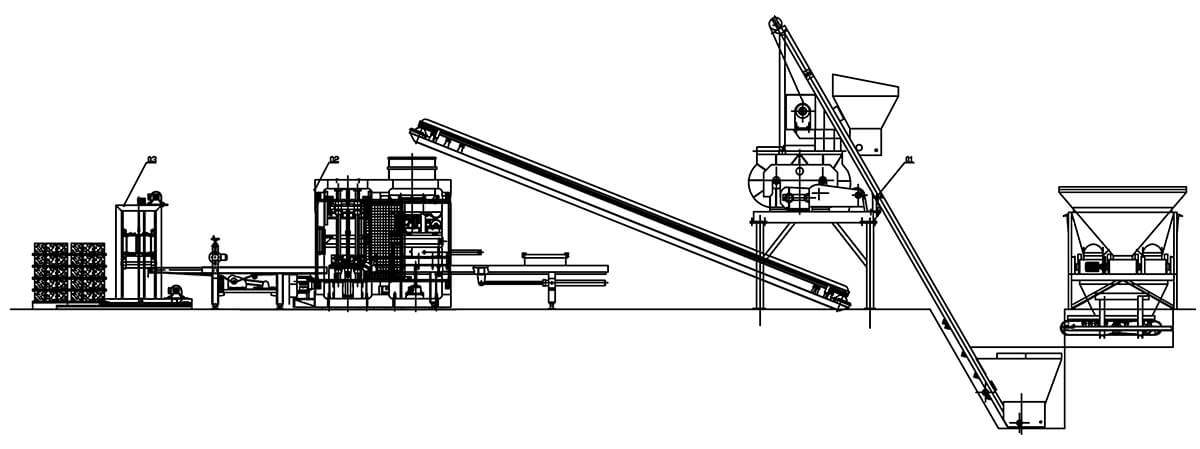

——Simple Automatic Production Line——

|

Simple Automatic Concrete Block Production Line: Items |

||

| 1 Automatic Batching Station | 2 Cement Silo | 3 Screw Conveyor |

| 4 Cement Scale | 5 Compulsory Mixer | 6 Belt Conveyor |

| 7 Pallet Conveying System | 8 Concrete Block Machine | 9 Face Mix Section |

| 10 Blocks Conveying System | 11 Automatic Stacker | 12 Fork Lift |

| 13 Wheel Loader | ||

Automatic batching station

Compulsory mixer

—— Production Capacity——

★Other brick sizes not mentioned may provide drawings to inquire about specific production capacity.

Product detail pictures:

Related Product Guide:

So as to provide you with ease and enlarge our business, we even have inspectors in QC Crew and guarantee you our best company and solution for Factory Price For Interlock Block Machine - Simple Automatic Concrete Block Production Line – Honcha , The product will supply to all over the world, such as: Algeria, Chile, America, We have more than 200 staff including experienced managers, creative designers, sophisticated engineers and skilled workers. Through hard work of all employees for the past 20 years own company grew stronger and stronger. We always apply the "client first" principle. We also always fulfill all contracts to the point and therefore enjoy excellent reputation and trust among our customers. You are very welcome to personally visit our company.We hope to start a business partnership on the basis of mutual benefit and successful development . For more information please do no hesitate to contact us..

This is a honest and trustworthy company, technology and equipment are very advanced and the prodduct is very adequate, there is no worry in the suppliment.

+86-13599204288

+86-13599204288