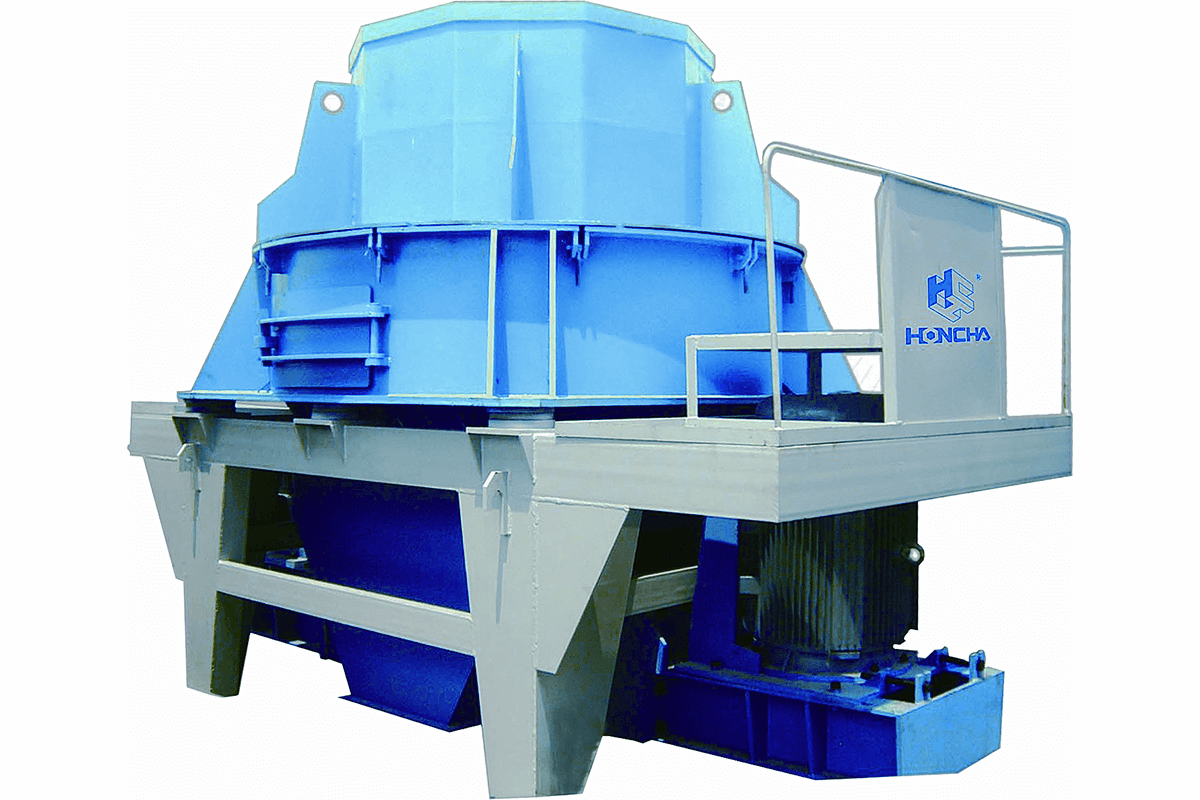

Competitive Price for Automatic Soil Brick Making Machine - Crushing sand washing equipment – Honcha

Competitive Price for Automatic Soil Brick Making Machine - Crushing sand washing equipment – Honcha Detail:

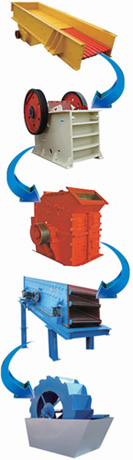

Honcha concrete crushing production line is based on the results of the latest R&D and design of China’s working conditions. It is mainly used in artificial sand production equipment such as broken solid building waste, river pebbles, mountain rocks, ore tailings, and stone chips, which can protect resources and can be turned into waste for profit. Both environmental protection and economic benefits can be obtained from the use of waste. It is a high-performance sand breaking equipment in China. The equipment provides high-quality sand and stone aggregate for highways, high-speed rail, high-rise buildings, municipalities, hydropower dams, and concrete mixing stations. It is the preferred equipment for artificial sand and river stone shaping.

——Technical Specification——

| Technical Specification | |||||||

| Technical parameters of vibration feeding machine | |||||||

| Model No. | Funnel Dimension(mm) | Maximum Feeding(mm) | Capacity(t/h) | Power(kw) | Weight(kg) | Outlet Dimension(mm) | |

| HCM850X3000 | 850X3000 | 400 | 80-120 | 7.5 | 3895 | 3110X1800X1600 | |

| HCM960X3800 | 960X3800 | 500 | 120-210 | 11 | 3980 | 3850X1950X1630 | |

| HCM1100X4200 | 1100X4200 | 580 | 200-430 | 15 | 4170 | 4400X2050X1060 | |

| HCM1300X4900 | 1300X4900 | 650 | 450-600 | 22 | 5200 | 5200X2350X1750 | |

| Jaw Crusher | |||||||

| Model No. | Feeding port(mm) | Maximum Feeding(mm) | Adjustable range(mm) | Maximum Feeding(mm) | Power(kw) | Outlet Dimension(mm) | Weight(kg) |

| HCR500X750 | 500X750 | 425 | 50-100 | 40-110 | 45-55 | 2035X1921X2000 | 12 |

| HCR600X900 | 600X900 | 480 | 65-160 | 90-180 | 55-75 | 2290X2206X2370 | 17 |

| HCR750X1060 | 750X1060 | 630 | 80-140 | 110-320 | 90-110 | 2655X2303X3110 | 29 |

| HCR900X1200 | 900X1200 | 750 | 95-165 | 220-450 | 110-132 | 3800X3166X3045 | 52 |

| Counterattack Crusher | |||||||

| Model No. | Feeding port(mm) | Maximum Feeding(mm) | Capacity(t/h) | Power(kw) | Weight(kg) | Specification(kg) | |

| EX-1007 | 400X730 | <250 | 15-60 | 37-55 | 9.5 | Ø1000X700 | |

| EX-1010 | 400X1080 | <300 | 50-90 | 55-75 | 14 | Ø1000X1050 | |

| EX-1210 | 400X1080 | <300 | 70-130 | 110-132 | 17 | Ø1250X1050 | |

| EX-1214 | 400X1430 | <300 | 90-180 | 132-160 | 22 | Ø1250X1400 | |

| Vibration sieve | |||||||

| Model No. | Sieve specification(mm) | Layer No. | Filter size(mm) | Feeding size(mm) | Capacity(t/h) | Vibration frequency(r/min) | Power(kw) |

| ZDS1237 | 1200X3700 | 1 | 4-50 | ≤200 | 10-80 | 960 | 5.5X2 |

| 2ZDS1237 | 1200X3700 | 2 | 4-50 | ≤200 | 10-80 | 960 | 5.5X2 |

| 2YK1548 | 4800X1500 | 2 | 3-100 | ≤400 | 30-275 | 870 | 15 |

| 3YK1548 | 4800X1500 | 3 | 3-100 | ≤400 | 30-275 | 870 | 15 |

| 2YK1848 | 4800X1800 | 2 | 3-100 | ≤400 | 56-330 | 870 | 18.5 |

| 3YK1848 | 4800X1800 | 3 | 3-100 | ≤400 | 56-330 | 870 | 18.5 |

| 2YK1860 | 6000X1800 | 2 | 3-100 | ≤400 | 65-586 | 870 | 22 |

| 3YK1860 | 6000X1800 | 2 | 3-100 | ≤400 | 65-586 | 870 | 22-30 |

| Technical parameters of the washing machine | |||||||

| Model No. | Impeller specification(mm) | Impeller speed(mm) | Maximum feeding(mm) | Type of reducer | Capacity(t/h) | Outlet Dimension(mm) | Power(kw) |

| XSD2610 | 2600X1000 | 1.178 | ≤10 | ZQ50-50-I-Z | 20-50 | 3255X1982X2690 | 5.5 |

| XSD2816 | 2800X1600 | 1.177 | ≤10 | ZQ50-50-I-Z | 30-60 | 3540X3000X2800 | 7.5-11 |

| XSD3016 | 3000X1600 | 1.179 | ≤10 | ZQ50-50-I-Z | 50-120 | 3845X3000X3080 | 11-15 |

Product detail pictures:

Related Product Guide:

To create more value for customers is our business philosophy; customer growing is our working chase for Competitive Price for Automatic Soil Brick Making Machine - Crushing sand washing equipment – Honcha , The product will supply to all over the world, such as: Argentina, Belarus, Thailand, In order to meet our market demands, we have paied more attention to the quality of our products and services. Now we can meet customers' special requirements for special designs. We persistently develop our enterprise spirit "quality lives the enterprise, credit assures cooperation and keep the motto in our minds: customers first.

Adhering to the business principle of mutual benefits, we have a happy and successful transaction, we think we will be the best business partner.

+86-13599204288

+86-13599204288