Big discounting Crushing Sand Washing Equipment - Semi Automatic Concrete Block Production Line – Honcha

Big discounting Crushing Sand Washing Equipment - Semi Automatic Concrete Block Production Line – Honcha Detail:

——Features——

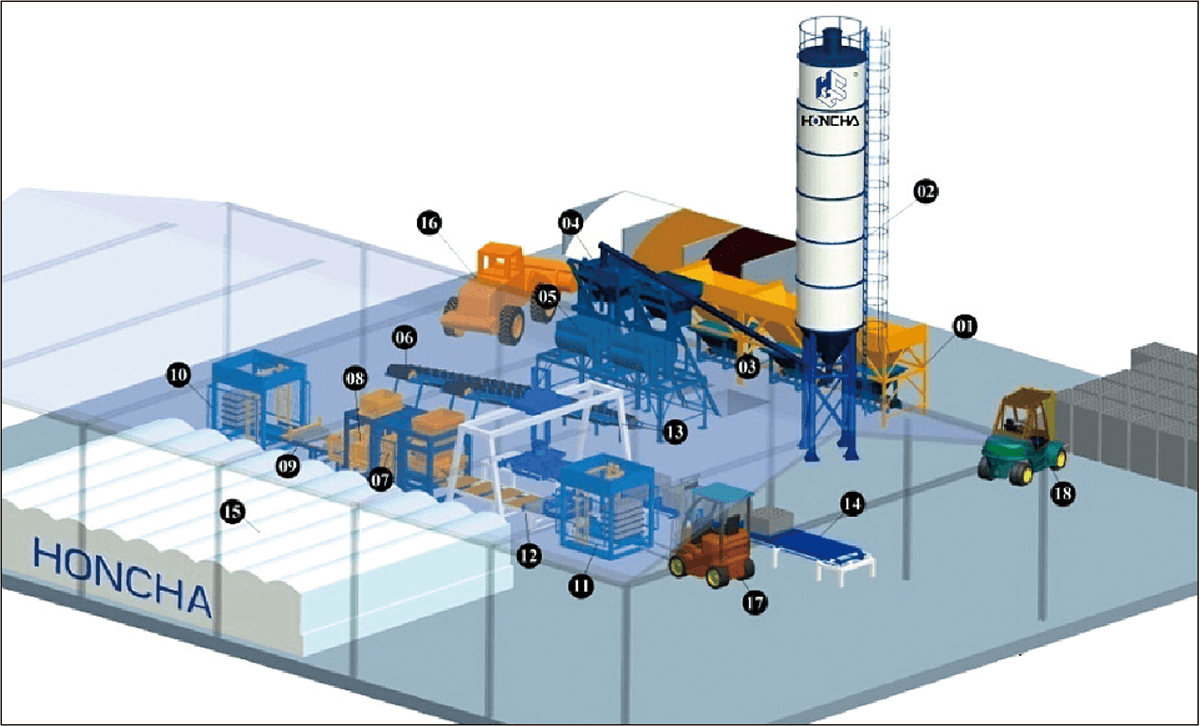

Semi automatic line: the wheel loader will put different aggregates in the Batching Station, it will measure them to the required weight and then combine with the cement from cement silo. All of the materials will then be sent to the mixer. After being mix evenly, the belt conveyer will convey the materials to the Block Making Machine. The finished blocks will be transferred to the Automatic Stacker. Then the fork lift will take all pallets of blocks to the curing chamber for curing. And pallet tumbler can get rid of the pallets one by one and then Automatic cuber will take the blocks and stack them to a pile, then the fork clamp can take the finished blocks to the yard for sales.

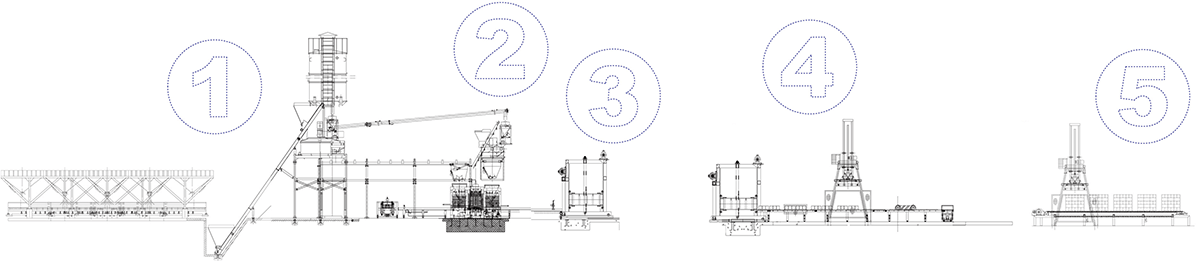

——Component——

1 Batching and Mixing Plant

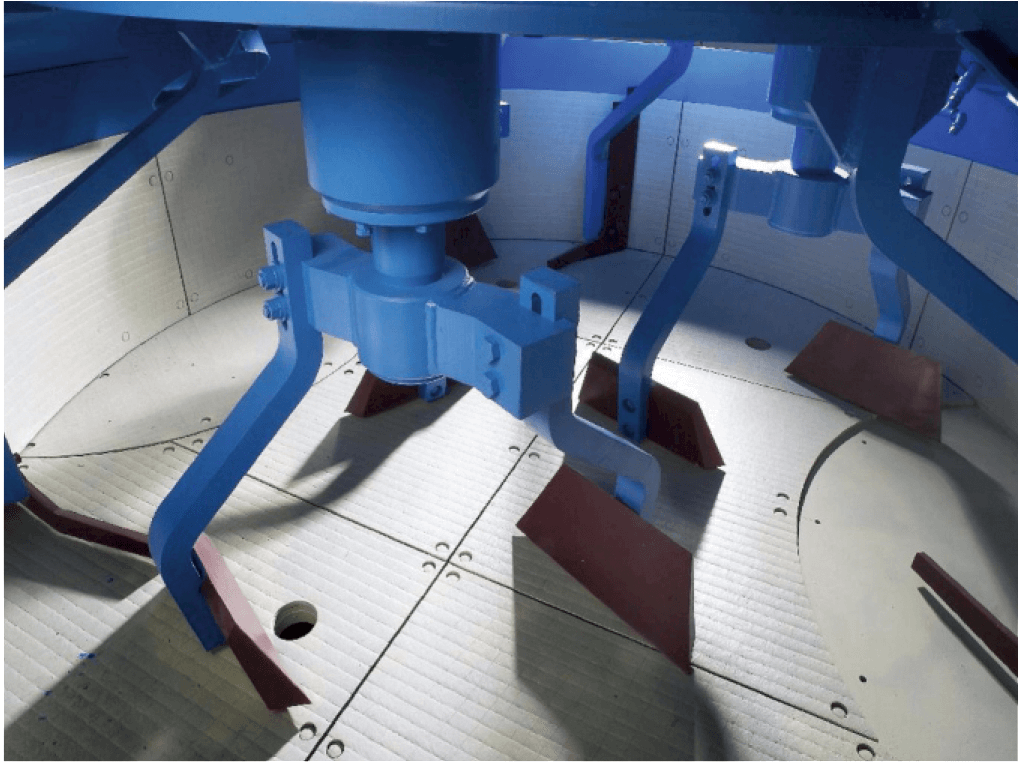

The batching and mixing system consists of a multi-component batching station which automatically weighs and conveys the aggregate to the compulsory mixer. The cement is transported from the cement silo using a screw conveyor and automatically weighed at the mixer. Once the mixer has completed its cycle the concrete will be transported using our overhead skip system to the fully automatic block machine system.

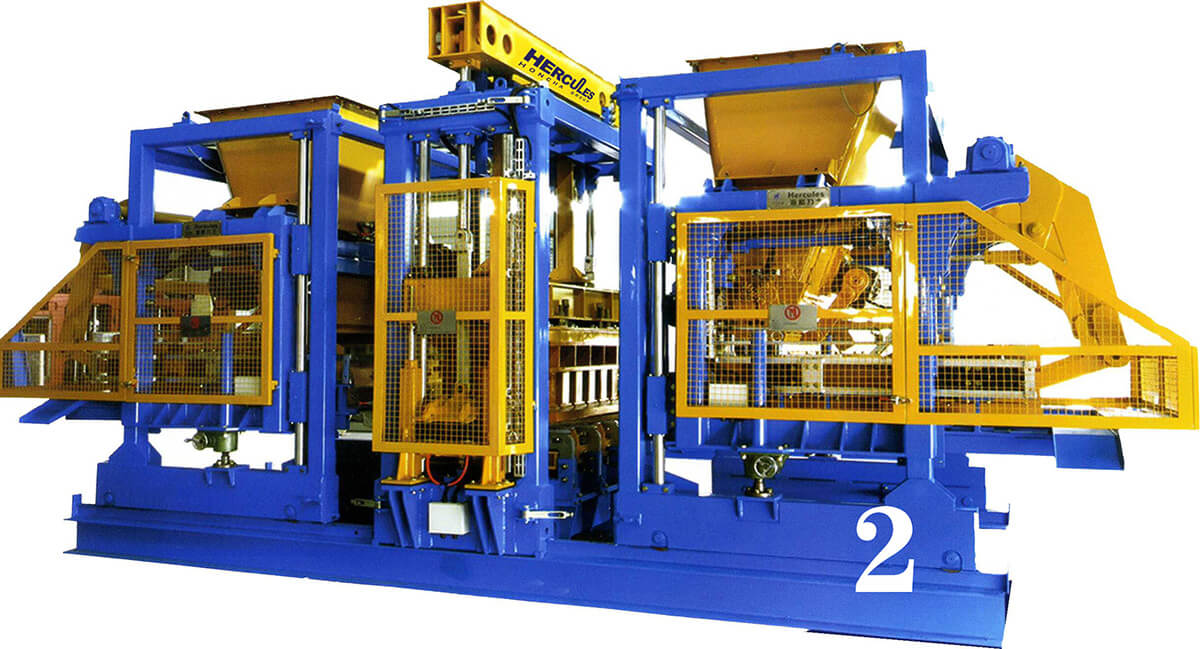

2、Block machine

The concrete is pushed into place by a feeder box and spread evenly into the bottom female mould. The top male mould is then inserted into the bottom mould and the use synchronized table vibration from both moulds to compact the concrete into the desired block. The machine can have a fully automatic face mix section added to allow the production of colored pavers.

Optional block machine models: Hercules M, Hercules L, Hercules XL.

3、Stacker

The fresh blocks are cleaned to make sure they are all the same height and then transported to the stacker. Then the fork lift will take all pallets of blocks to the curing chamber for curing.

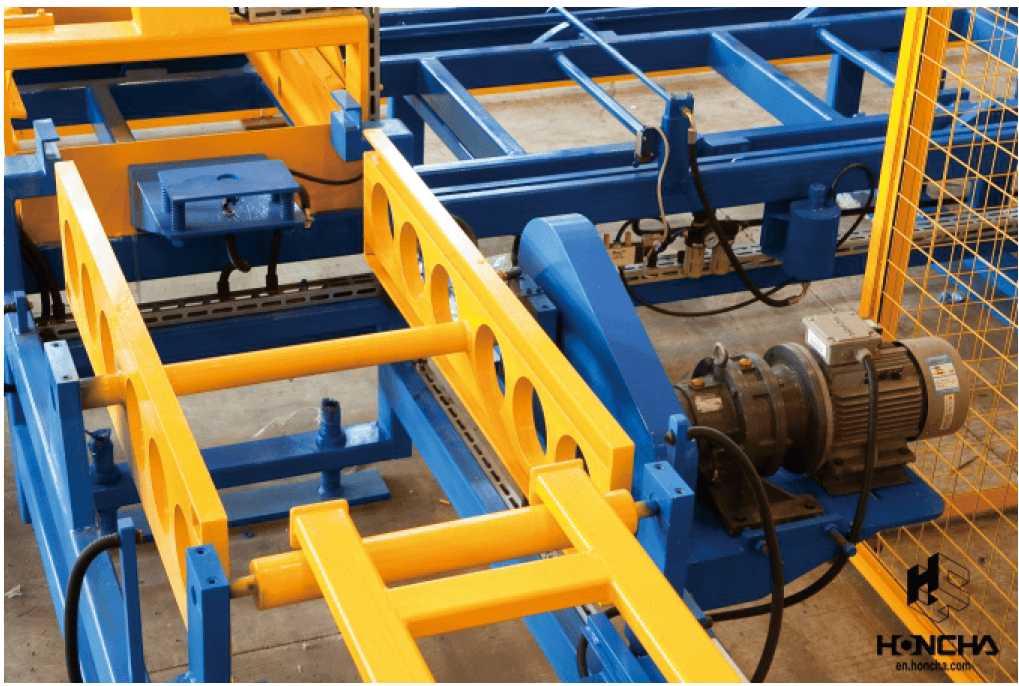

4、Un-stacker

When the pallets have been fully loaded into the un-stacker is automatically unloaded on to the pallet return system and aligned ready for the cubing system.

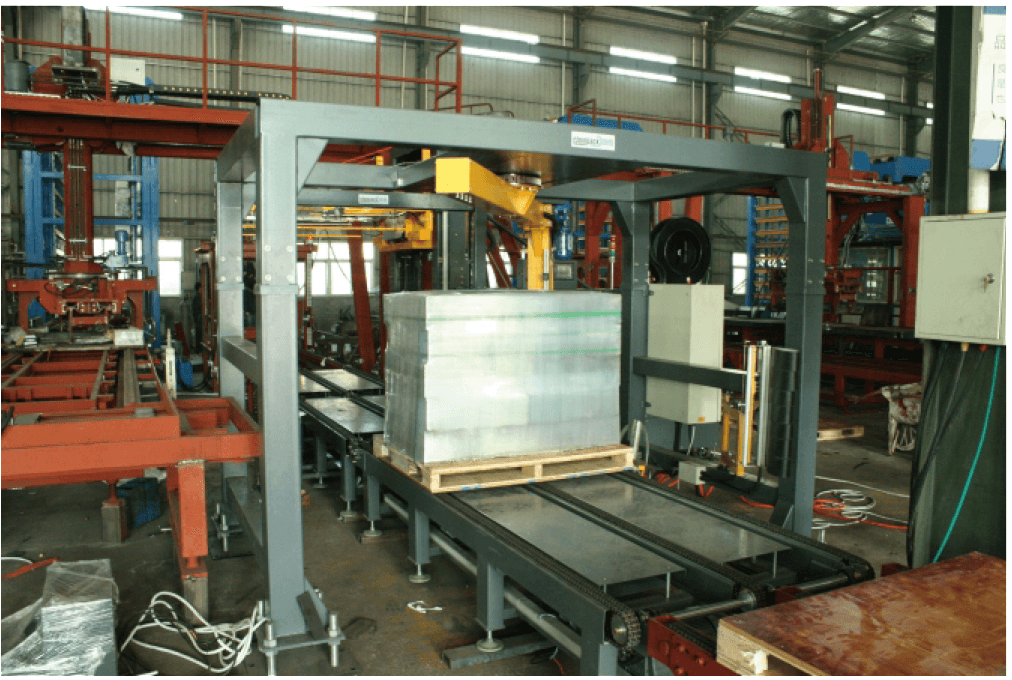

5、Automatic Gantry Type Block Cubing System

The cubing system will collect the blocks or pavers from two pallets at a time and cross stack them onto the exit conveyor. It is equipped with four rubber covered clamping arms and hydraulically operated with 360 degree horizontal movement.

——Semi Automatic Production Line——

|

Semi Automatic Concrete Block Production Line: Items |

||

| 1 Automatic Batching Station | 2 Cement Silo | 3 Screw Conveyor |

| 4 Cement Scale | 5 Compulsory Mixer | 6 Belt Conveyor |

| 7 Concrete Block Machine | 8 Face Mix Section | 9 Blocks Conveying System |

| 10 Stacker | 11 Un-stacker | 12 Pallet Conveying System |

| 13 Automatic Cuber | 14 Exit Conveyor | 15 Curing Chamber |

| 16 Wheel Loader | 17 Fork Lift | 18 Fork Clamp |

Compulsory mixer

Automatic batching station

Wrapping machine

Pallet turn over

—— Production Capacity——

★Other brick sizes not mentioned may provide drawings to inquire about specific production capacity.

| Production capacity | ||||||

| Hercules M | Prouduction Boards:1400*900 Production Area:1300*850 Stone Height:40~500mm | |||||

| Proudct | Size(mm) | Face mix | Pcs/cycle | Cycles/min | Prodcution/8h | Production cubic m/8h |

| Standard Brick | 240×115×53 | X | 60 | 4 | 115,200 | 169 |

| Hollow block | 400*200*200 | X | 12 | 3.5 | 20,160 | 322 |

| Hollow block | 390×190×190 | X | 12 | 3.5 | 20,160 | 284 |

| Hollow Brick | 240×115×90 | X | 30 | 3.5 | 50,400 | 125 |

| Paver | 225×112.5×60 | X | 30 | 4 | 57,600 | 87 |

| Paver | 200*100*60 | X | 42 | 4 | 80,640 | 97 |

| Paver | 200*100*60 | O | 42 | 3.5 | 70,560 | 85 |

| Hercules L | Prouduction Boards:1400*1100 Production Area:1300*1050 Stone Height:40~500mm | |||||

| Proudct | Size(mm) | Face mix | Pcs/cycle | Cycles/min | Prodcution/8h | Production cubic m/8h |

| Standard Brick | 240×115×53 | X | 80 | 4 | 153,600 | 225 |

| Hollow block | 400*200*200 | X | 15 | 3.5 | 25,200 | 403 |

| Hollow block | 390×190×190 | X | 15 | 4 | 14,400 | 203 |

| Hollow Brick | 240×115×90 | X | 40 | 4 | 76,800 | 191 |

| Paver | 225×112.5×60 | X | 40 | 4 | 76,800 | 116 |

| Paver | 200*100*60 | X | 54 | 4 | 103,680 | 124 |

| Paver | 200*100*60 | O | 54 | 3.5 | 90,720 | 109 |

| Hercules XL | Prouduction Boards:1400*1400 Production Area:1300*1350 Stone Height:40~500mm | |||||

| Proudct | Size(mm) | Face mix | Pcs/cycle | Cycles/min | Prodcution/8h | Production cubic m/8h |

| Standard Brick | 240×115×53 | X | 115 | 4 | 220,800 | 323 |

| Hollow block | 400*200*200 | X | 18 | 3.5 | 30,240 | 484 |

| Hollow block | 390×190×190 | X | 18 | 4 | 34,560 | 487 |

| Hollow Brick | 240×115×90 | X | 50 | 4 | 96,000 | 239 |

| Paver | 225×112.5×60 | X | 50 | 4 | 96,000 | 146 |

| Paver | 200*100*60 | X | 60 | 4 | 115,200 | 138 |

| Paver | 200*100*60 | O | 60 | 3.5 | 100,800 | 121 |

Product detail pictures:

Related Product Guide:

Our business puts emphasis over the administration, the introduction of talented staff, plus the construction of team building, attempting hard to boost the standard and liability consciousness of personnel customers. Our corporation successfully attained IS9001 Certification and European CE Certification of Big discounting Crushing Sand Washing Equipment - Semi Automatic Concrete Block Production Line – Honcha , The product will supply to all over the world, such as: Portland, Guatemala, Mumbai, Merchandise have been exported to Asia, Mid-east,European and Germany market. Our company has constantly been able to update the items performance and safety to meet the markets and strive to be top A on stable quality and sincere service. If you have the honor to do business with our company. we'll undoubtedly do our very best to support your business in China.

The product classification is very detailed that can be very accurate to meet our demand, a professional wholesaler.

+86-13599204288

+86-13599204288