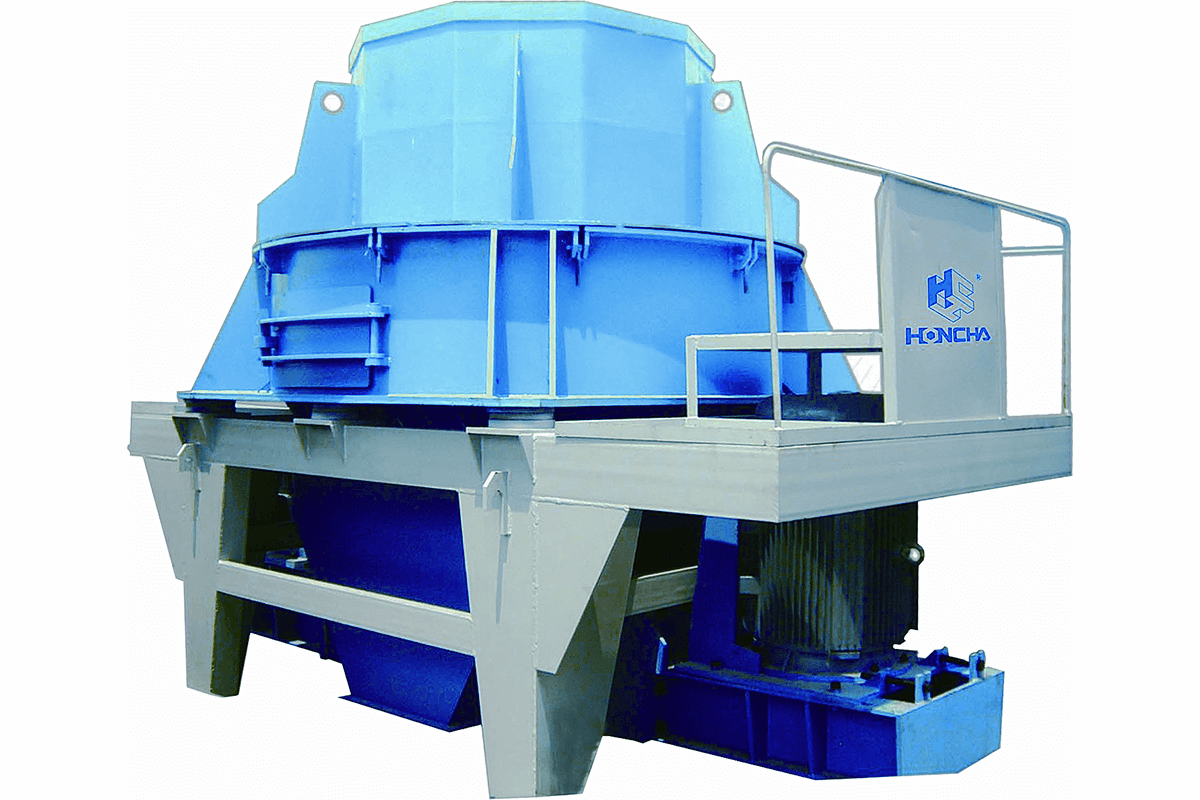

100% Original Factory Brick Concrete Block Making Machine - Crushing sand washing equipment – Honcha

100% Original Factory Brick Concrete Block Making Machine - Crushing sand washing equipment – Honcha Detail:

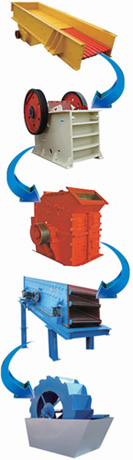

Honcha concrete crushing production line is based on the results of the latest R&D and design of China’s working conditions. It is mainly used in artificial sand production equipment such as broken solid building waste, river pebbles, mountain rocks, ore tailings, and stone chips, which can protect resources and can be turned into waste for profit. Both environmental protection and economic benefits can be obtained from the use of waste. It is a high-performance sand breaking equipment in China. The equipment provides high-quality sand and stone aggregate for highways, high-speed rail, high-rise buildings, municipalities, hydropower dams, and concrete mixing stations. It is the preferred equipment for artificial sand and river stone shaping.

——Technical Specification——

| Technical Specification | |||||||

| Technical parameters of vibration feeding machine | |||||||

| Model No. | Funnel Dimension(mm) | Maximum Feeding(mm) | Capacity(t/h) | Power(kw) | Weight(kg) | Outlet Dimension(mm) | |

| HCM850X3000 | 850X3000 | 400 | 80-120 | 7.5 | 3895 | 3110X1800X1600 | |

| HCM960X3800 | 960X3800 | 500 | 120-210 | 11 | 3980 | 3850X1950X1630 | |

| HCM1100X4200 | 1100X4200 | 580 | 200-430 | 15 | 4170 | 4400X2050X1060 | |

| HCM1300X4900 | 1300X4900 | 650 | 450-600 | 22 | 5200 | 5200X2350X1750 | |

| Jaw Crusher | |||||||

| Model No. | Feeding port(mm) | Maximum Feeding(mm) | Adjustable range(mm) | Maximum Feeding(mm) | Power(kw) | Outlet Dimension(mm) | Weight(kg) |

| HCR500X750 | 500X750 | 425 | 50-100 | 40-110 | 45-55 | 2035X1921X2000 | 12 |

| HCR600X900 | 600X900 | 480 | 65-160 | 90-180 | 55-75 | 2290X2206X2370 | 17 |

| HCR750X1060 | 750X1060 | 630 | 80-140 | 110-320 | 90-110 | 2655X2303X3110 | 29 |

| HCR900X1200 | 900X1200 | 750 | 95-165 | 220-450 | 110-132 | 3800X3166X3045 | 52 |

| Counterattack Crusher | |||||||

| Model No. | Feeding port(mm) | Maximum Feeding(mm) | Capacity(t/h) | Power(kw) | Weight(kg) | Specification(kg) | |

| EX-1007 | 400X730 | <250 | 15-60 | 37-55 | 9.5 | Ø1000X700 | |

| EX-1010 | 400X1080 | <300 | 50-90 | 55-75 | 14 | Ø1000X1050 | |

| EX-1210 | 400X1080 | <300 | 70-130 | 110-132 | 17 | Ø1250X1050 | |

| EX-1214 | 400X1430 | <300 | 90-180 | 132-160 | 22 | Ø1250X1400 | |

| Vibration sieve | |||||||

| Model No. | Sieve specification(mm) | Layer No. | Filter size(mm) | Feeding size(mm) | Capacity(t/h) | Vibration frequency(r/min) | Power(kw) |

| ZDS1237 | 1200X3700 | 1 | 4-50 | ≤200 | 10-80 | 960 | 5.5X2 |

| 2ZDS1237 | 1200X3700 | 2 | 4-50 | ≤200 | 10-80 | 960 | 5.5X2 |

| 2YK1548 | 4800X1500 | 2 | 3-100 | ≤400 | 30-275 | 870 | 15 |

| 3YK1548 | 4800X1500 | 3 | 3-100 | ≤400 | 30-275 | 870 | 15 |

| 2YK1848 | 4800X1800 | 2 | 3-100 | ≤400 | 56-330 | 870 | 18.5 |

| 3YK1848 | 4800X1800 | 3 | 3-100 | ≤400 | 56-330 | 870 | 18.5 |

| 2YK1860 | 6000X1800 | 2 | 3-100 | ≤400 | 65-586 | 870 | 22 |

| 3YK1860 | 6000X1800 | 2 | 3-100 | ≤400 | 65-586 | 870 | 22-30 |

| Technical parameters of the washing machine | |||||||

| Model No. | Impeller specification(mm) | Impeller speed(mm) | Maximum feeding(mm) | Type of reducer | Capacity(t/h) | Outlet Dimension(mm) | Power(kw) |

| XSD2610 | 2600X1000 | 1.178 | ≤10 | ZQ50-50-I-Z | 20-50 | 3255X1982X2690 | 5.5 |

| XSD2816 | 2800X1600 | 1.177 | ≤10 | ZQ50-50-I-Z | 30-60 | 3540X3000X2800 | 7.5-11 |

| XSD3016 | 3000X1600 | 1.179 | ≤10 | ZQ50-50-I-Z | 50-120 | 3845X3000X3080 | 11-15 |

Product detail pictures:

Related Product Guide:

"Sincerity, Innovation, Rigorousness, and Efficiency" is the persistent conception of our company for the long-term to develop together with customers for mutual reciprocity and mutual benefit for 100% Original Factory Brick Concrete Block Making Machine - Crushing sand washing equipment – Honcha , The product will supply to all over the world, such as: Croatia, Malawi, Islamabad, The development of our company not only needs the guarantee of quality, reasonable price and perfect service, but also relies on our customer's trust and support! In the future, we are going to continue with the most qualified and high quality service to offer the most competitive price, Together with our customers and achieve win-win! Welcome to inquiry and consult!

We have been appreciated the Chinese manufacturing, this time also did not let us disappoint,good job!

+86-13599204288

+86-13599204288